Inline Plastics, Inc. is an industry leader in custom profile extrusions. From custom color plastic extrusions to deburring, our capabilities are as widely varied as our customers. More importantly, our service is second-to-none. Inline Plastics offers the highest quality, at the best price, with the quickest reaction time for all custom profile extrusions.

The business of Inline Plastics is not only about extrusion dies and custom plastic extrusions. We also offer additional inline processes. These include, but are not limited to:

Custom Plastic Profiles

Inline Plastics has an extensive portfolio of extrusion capabilities that allow us to create a wide variety of custom plastic profiles. Our anti-static, co-extrusion, single-screw, and foamed profile processes allow us to tailor enclosed, hollow, and open profiles with U/H/C/T channels. We have considerable experience working with a variety of thermoplastics, from acrylic and polycarbonate to ABS, HDPE, LDPE, and PVC. We are capable of processing a wide range of production scales, including prototypes, low-volume, and large-scale runs.

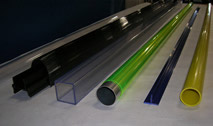

Custom Plastic Tubing

As a leading provider of custom extruded plastic tubing, Inline Plastics has the expertise and technology to integrate the latest resins and additives, ensuring we can meet the demands of nearly any application. We have experience producing a wide range of tube and piping designs – including custom slit tubes, grow tubes, and translucent green and beige piping – in sizes ranging from 0.018 inches up to 6 inches in diameter, but not limited to this range. Industries we’ve served include medical, agriculture, consumer packaged goods, industrial applications, and bulk laminate, tape, and paper roll cores. While our custom plastic tubing is typically composed of polyethylene, we are able to incorporate a variety of other materials and additives to enhance particular characteristics.

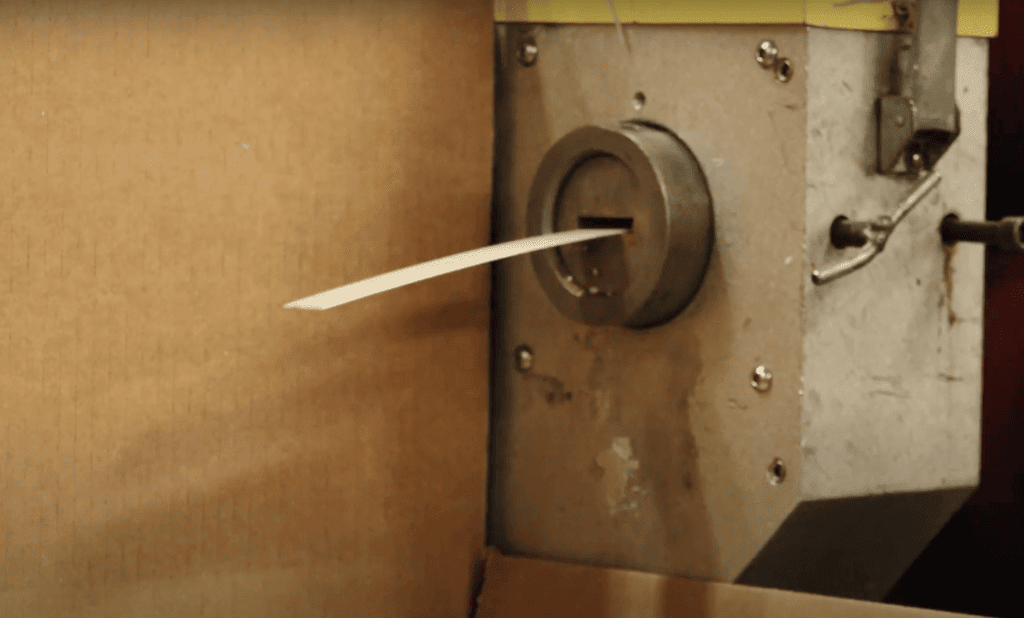

Die Creation/Mold Making

Dies and molds are the components used to shape raw extrusion material into the desired form. The process of manufacturing them is known as die creation or mold making. The dies and molds are especially important for the creation of a particularly-sized tube or profile before it hits mass production. The creation of a die is crucial to cutting or shaping a material to a specified shape/size. During the mold making process, a “reverse model part” is made, which can then be used to create an enormous supply of duplicates of the original shape or part.

Plastic Extrusion Services

At Inline Plastics, we pride ourselves on providing the highest quality plastic extrusion services possible. As a highly versatile manufacturing method, plastic extrusion allows us to produce accurate and repeatable plastic products and components from a variety of plastic formulations. Whether you are in need of custom profiles, tubes and piping, or plastic containers, Inline Plastics has the materials and equipment to create your product with the utmost quality, speed, and efficiency.

Plastic Extrusion Die Development

Inline Plastics is pleased to offer extrusion die development services. In addition to our plastic extrusion expertise, we are capable of helping you design and develop custom extrusion dies specifically engineered for your project. As an industry leader in plastic extrusion, we have the resources and expertise necessary to ensure that your die is engineered and manufactured with the correct drawdown, land length, material specification, and compression capabilities.

Thermoplastics

When designing your custom plastic product, material selection is critical. Inline Plastics has experience working with an extensive range of thermoplastic materials that can be used to create a variety of extruded products. Thermoplastics are valued for their hardness and versatility, and can be mixed with additives in order to enhance certain material characteristics, such as color, hardness, UV resistance, and flexibility. Some of the most common thermoplastics include ABS, PVC, HDPE, LDPE, and polyethylene. Thermoplastics are used to create products for a wide range of industries, from aerospace and automotive components to beverage bottles and pharmaceutical containers.

Secondary Services

Inline Plastics offers a variety of secondary services applied in line at no additional cost, including:

- Double-backed tape

- Embossing

- Foam tape and pressure-sensitive adhesive (PSA) tape

- Inline hole drilling

- Velcro

For an additional fee, we are pleased to provide the following secondary services:

- Deburring

- Drilling (notching, hole punching, routing, and more)

- Packaging to customer’s designs (packaging & assembly)

About Inline Plastics, Inc.

Inline Plastics will keep your project on budget. We stand behind our pricing, and we are also able to cut back on other costs. Because we do most off-line secondary operations during the actual extrusion process, we can eliminate the high costs associated with those secondary operations. Let us show you, through our state-of-the-art quote system.

Contact Inline Plastics for your next extrusion die project, or fill out an RFQ form today and we can fax a price quote in a matter of minutes.

- Quality, Price, and Reaction Time in Extrusions

- All Parts Made to Specification within Quoted Tolerance

Mission Statement

75 Years of Experience in Custom Plastic Extrusion

“Quality, Price and Reaction Time Makes the Inline Difference”

Delivery is 2nd to none going above and beyond customers’ extrusion needs.

Quality, Price, and Reaction Time in Extrusions

All Parts 100% Guaranteed