Plastic tubing is hollow tubing made from plastic materials. It is used in applications ranging from fluid flow and structural systems to sheathing or insulation for heating or electrical assemblies. Plastic tubing is highly versatile and can be manufactured to be either rigid or flexible, depending on the needs of the application. To ensure that you have the correct tubing for your project, it is important to choose the right material, size, and design. A wide variety of standard tubing is available; however, custom tubing is often better for more complex or specialized applications.

What Is Plastic Tubing?

Plastic tubing is composed of a mixture of polymer materials and various chemicals to create a rigid or flexible blend. Different materials offer unique benefits, such as enhanced toughness, abrasion resistance, and temperature resistance. The majority of plastic tubing is manufactured using the following methods:

Extrusion

Extruded plastic tubing is created when molten plastic material is pushed through a pre-cut die with the desired diameter. The plastic exits the die in one consistent strand and cools into the desired shape. As the tube lengthens, the plastic tube extrusion equipment cuts the plastic to the required length, for precise tubing that exhibits regular dimensions along its entire length.

Choosing The Right Type Of Plastic Tubing For Your Next Project

Plastic tubing is available in a wide variety of materials. To ensure that you have the right material for the job, it is important to understand the physical properties of different types of plastic tubing. Some of the most common types of plastic tubing include:

- ABS

- Ethyl Vinyl Acetate (EVA)

- Nylon (polyamide)

- Polycarbonate

- Polyethylene (PE)

- Low & High-Density Polyethylene (LDPE & HDPE)

- Polypropylene (PP)

- Polyurethane (PU)

- Polyvinyl Chloride (PVC)

Plastic tubing materials offer unique advantages for specific applications. Some polymers offer enhanced heat resistance, while others maintain flexibility in extreme cold. Other important features incorporated into plastic tube designs include spark resistance, flame resistance, chemical resistance, reinforced structure, and enhanced sterilization.

Plastic Tubing Colors

Another important design consideration is the color of your plastic tubing. Some applications require that the user be able to see through the material to verify product quality, while others require the use of colored plastic tubes to help users safely identify specific materials. Plastic tubes are available in a broad range of colors and finishes, including clear, solid color, translucent, and multicolor tubing.

Applications For Plastic Tubing

The versatility of plastic tubing makes it extremely useful for a wide range of industrial and commercial applications. These include:

Mailing

Plastic tubing is used to deliver various items such as promotional materials, samples, literature, and more.

Pneumatic Systems

Flexible pneumatic tubing can handle the compression of a pneumatic system.

Banking

The carriers as well as the long tubes that carry items from the teller to the customer are made of thick-walled sturdy plastic tubing.

Farming

Plastic tubing is easy to install, long-lasting, corrosion- and rust-resistant, and durable. This makes it perfect for farming water systems.

Liquid

Plastic tubing is used in a wide range of liquid processing applications. In the case of beverages, plastic tubing can be made from FDA-grade plastic to meet standards for cleanliness, temperature, and pressure.

Automotive

Due to its flexibility and endurance, plastic tubing is suitable for fuel lines and fuel fillers in automotive applications.

Marine

Like the automotive industry, the marine industry relies on plastic tubing for various marine equipment such as bilge pump tubing.

Medicine

Medical grade plastic tubing can be used to transport fluids to and from the body.

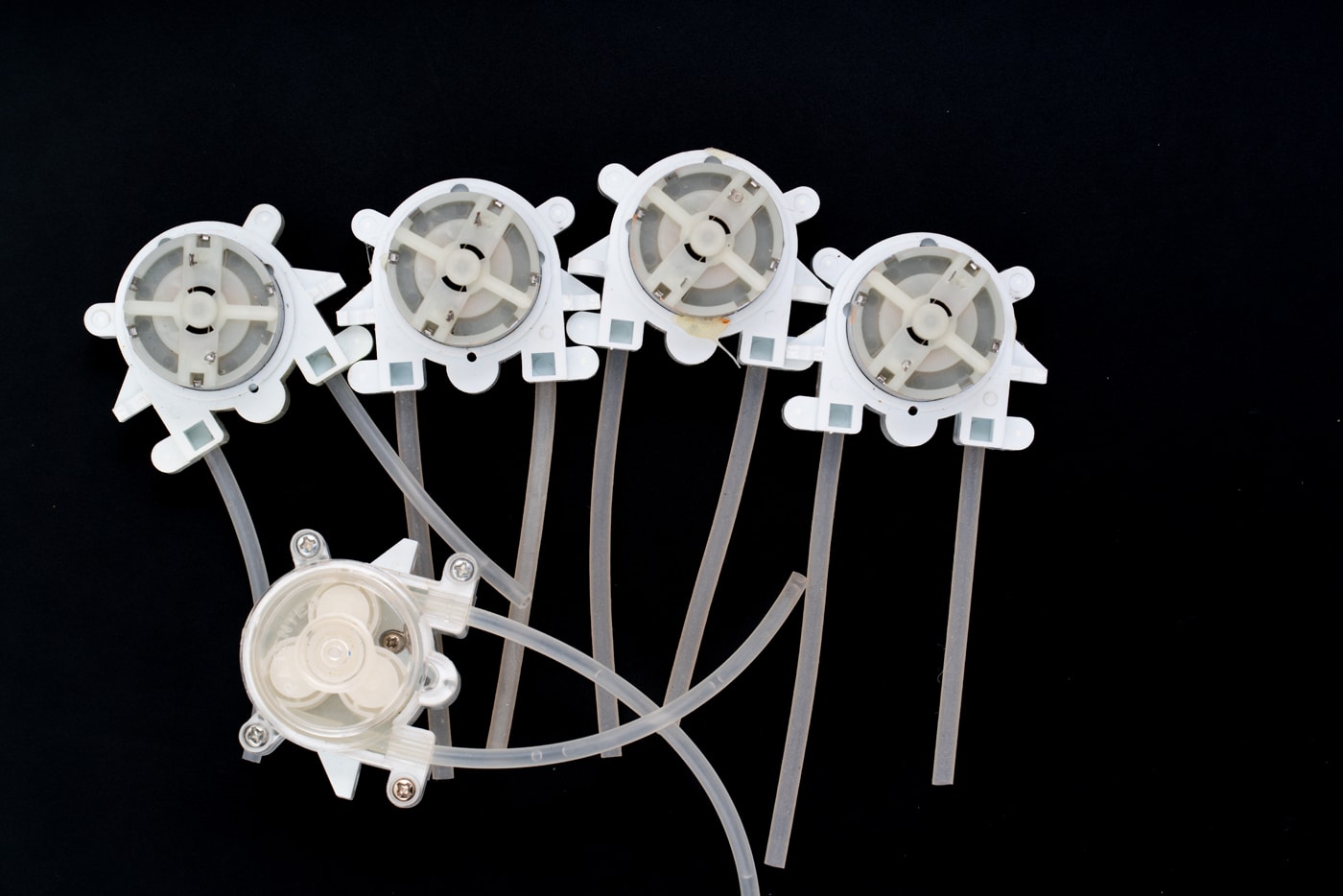

Peristaltic Pump

Peristaltic pumps use flexible yet durable plastic tubing to transmit power through fluid displacement.

Food and Beverage

Plastic tubing is used in the food and beverage industry to convey a variety of fluids in production and service settings.

Industrial and Commercial Cleaning Equipment

Heavy-duty cleaning equipment in industrial and commercial settings requires dependable plastic tubes to transport and disseminate water and cleaning solutions.

Benefits & Advantages Of Plastic Tubing

Plastic tubing is made from a wide variety of polymer materials, which are chosen for characteristics such as cost, corrosion and rust resistance, endurance, and strength. Other benefits of plastic tubing include:

Functionality

Plastic tubing is manufactured to be resistant to the specific elements it will be exposed to, making it extremely functional.

Durability

Plastics used in plastic tubing are strong and durable, with options for extra toughness, abrasion resistance, wear resistance, and corrosion resistance.

Versatility

Due to the wide variety of plastic tubing designs and materials available, plastic tubing is useful for virtually any application.

Cost-Effective

Plastics are less expensive and last longer than other forms of tubing.

Recyclable

Plastics used in plastic tubing are recyclable for a more sustainable product.

Custom Plastic Tubing Services At Inline Plastics, Inc.

Whether you require plastic water tubes for your water filtration system or quality tubing for pneumatic equipment, Inline Plastics has the material, equipment, and skill necessary to provide you with the perfect tubing and piping solution. In addition to our custom plastic tubing design and manufacturing services, we offer plastic pipe manufacturing, plastic profiles, and die creation. Our capabilities allow us to create many types of plastic pipe and plastic tubing to meet the needs of our highly diverse clientele. Visit our Materials Page to learn about the types of plastic water pipe and plastic tubing available.